What is manganese steel?

Manganese steel is a steel alloy containing 11-14% manganese. It’s often referred to as Hadfield steel, or Hadfield grade, as Sir Robert Hadfield discovered it in 1882. Manganese steel is non-magnetic and is less likely to rust than carbon steel.

What makes manganese steel special?

It has an extremely high impact strength and abrasion resistance in its hardened state. Manganese steel is a steel that works harder the more it’s used- you can’t say that for a lot of material. In fact, you’ll often hear it described as the “ultimate work hardening steel”. Manganese steel is also considered to be an extremely hard material to machine – it’s special in that way.

What does “Work Harden” mean?

The steel has self-hardening properties, so the more impact it takes, the harder the material becomes. Think of it as a self-renewing surface. It can achieve up to 3 times its surface hardness during impact without an increase in brittleness. Clifton Steel can pre-peen your manganese steel so it’s ready for service as soon as you get it if that’s something you need.

What is manganese used for in steel?

All steel has manganese in it! It removes oxygen and sulfur when iron ore is converted into iron, and it’s essential to convert iron into steel. Manganese decreases the brittleness of the steel and adds some toughness.

- MINING INDUSTRY – Excellent material for cement mixers, shovel buckets, rock crushers & sizers, or crawler treads.

- AGGREGATE INDUSTRY – Use for superior chute liners. As the chute work hardens, the surface of the steel becomes almost glossy, supporting material flow.

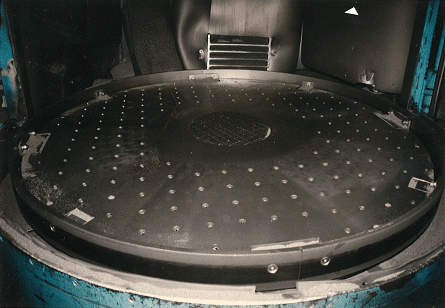

- STEEL CASTING & FORGING INDUSTRY – Ideal for shot blasting cabinet liners (top left) since it hardens the more the cabinet is used. Blasting cabinet conveyor rollers are another example.

- RAILROAD INDUSTRY – Commonly used for switches and crossings.

- RECYCLING & SCRAP INDUSTRY – Since manganese is nonmagnetic, it’s great for wear/impact plate for the bottom of electromagnets or separator drums (bottom left).

How do you cut or machine manganese steel?

Super common question about manganese is how to work with it. It’s not an easy material to machine or weld, it’s even describe it as having zero machinability. That’s not exactly the case. The reason it’s hard to work with is because the material hardens as it’s cut, so special tools and techniques are required. We’ve been doing this a long time and have the process perfected. Check out our page on Tensamang™ to read more about our machining capabilities.

Which is better, manganese steel or carbon steel?

That completely depends on the application. Manganese can reach a hardness score of almost 600 BHN, giving it about 5 times the hardness of mild steel, and almost 3 times the hardness of annealed stainless steel. That sounds great, but sometimes it’s not what you’re looking for or more than you need. Talk to a Clifton representative to find out if manganese is a good material for your project.

Did You Know?

The natural presence of manganese in the iron ore used by the Spartans is believed to be why their steel weapons were superior to those of their enemies – USGS