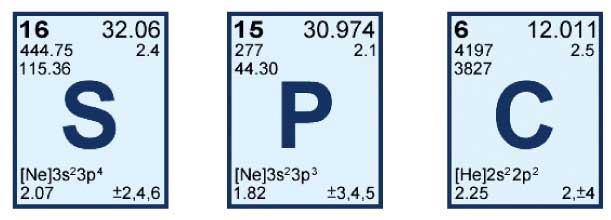

TENSALLOY™ is always within the restricted range for sulfur and phosphorus. Reduced levels of sulfur and phosphorus provide minimal inclusions, giving our product enhanced properties of strength and durability. Protect your equipment.

TENSALLOY™ is always controlled within a range of carbon

This ensures formability and weldability of materials. The principal hardening agent in steel is Carbon. Controlling the range of carbon provides durability of the product and assures the product can be readily fabricated without the negative effects of excessive carbon.

TENSALLOY™ is always vacuum degassed for cleanliness

Gases in excess are typical when melting steel. The degree and severity affects the product and performance. To reduce this condition, the melted steel is processed through an additional operation to control these gases.

TENSALLOY™ is always properly heat treated using approved processes

The heat treat phase of manufacturing consists of two processes.

- The initial process is the heating of the material above the critical temperature. The hardness of the product is produced by rapid cooling of the steel in this state.

- The steel is tempered by reheating it to a specified temperature for a specified length of time. Improper time and temperature is a shortcut that can cost you durability and performance. Tensalloy™ is your assurance of proper practices.

TENSALLOY™ is always properly inspected and quality controlled

In compliance with ISO-9001 standard for processes and materials, Tensalloy™ is subject to the most robust audited processes and practices in place in the market. It is your assurance from the time the steel is melted until the time it is rusted back into the ground!