Clifton Steel’s SLS600® induction hardened wear pipe is engineered for maximum life in highly abrasive applications, with a special chemistry and core hardened pipe.

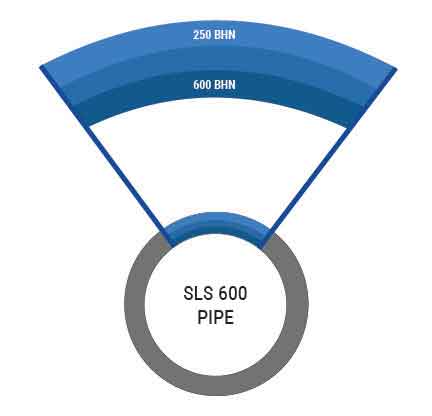

Induction hardened pipe is achieved by a unique heating/quenching process. This process alters the microstructure of the steel through the pipe wall, resulting in an inner surface hardness of 600 BHN. While the inner surface provides exceptional abrasion resistance, the outer surface cools slower, remaining more ductile, with a hardness of 250 BHN. The unique process allows the pipe to accommodate service and welding stresses.

This wear pipe is a highly economical solution to many of the abrasive wear problems found with carbon steel pipe. It is also a much more user and maintenance friendly option to replace the heavy, brittle cast piping often used to combat abrasion.

Advantages

- Outlasts mild steel pipe by average of 5+ times

- Reduces maintenance cost, & unplanned outages

- Wide range of diameters

- Standard pipe sizes

- Easy installation & field repair

- Monolithic material with no laminations

- Available in straights, bends, wyes, tees & reducers

- Abrasion resistant up to 450° F

- Tremendous design & fabrication flexibility

- Great replacement for heavy, unweldable castwear pipe

Comparison Based on Mild Steel

| Mild Steel | Induction Hardened Pipe | |

| Hardness | 120 – 150 BHN | 600 BHN |

| Max Temperature | 750° F | 450° F |

| Abrasion Resistant | Poor | Good |

| Impact Resistant | Good | Fair |

| Std. Sizes (OD) | Unlimited | 2.5″ to 24″ |

| Handling/ Installation | Excellent | Very Good |

| Fabrication | Unlimited | Some Limitations |

| Emergency Repair | Easily Patched | Easily Patched |

| Initial Cost | 1 | 3-4x |

| Life Expectancy | 1 | 4-6x |

| Min. Bend Radius | 20″ min. or 3x Diameter |

Hardness Profile

The outside surface is mild steel for easy welding.

Fabrication

We recommend the use of Clifton Steel’s fabrication services to eliminate processing and fabrication errors.

Cutting and forming

Induction wear pipe can be successfully cut with plasma cutting or an abrasive cut-off wheel. We do not recommend using Oxy-fuel. The pipe should never be cut lengthwise as the induction hardening process imparts internal stresses in the pipe wall.

Joint Preparation

Avoid welding areas of pipe that have tears, crack, or other imperfections. Area to be joined should have all loose scale, moisture, rust, grease, etc. removed within 1/2″ from welding joint.

Welding

As any heat applied to induction hardened pipe can affect the wear properties, consult with a Clifton Steel representative prior to welding. We do stock weld wire compatible with hardened pipe- Tensaweld Workmate.

Preheating & Interpass Temperatures

Preheat the weld zone and 6″ of the adjacent if ambient temperature of parts is below 70º F. Care must be taken to cool the inner surface. As temperatures approach 500º F the inner surface hardness will begin to decrease.

Welding with water cooling is the preferred method of welding. Be sure the water does not contact the exterior of the pipe. An alternate method without water cooling should only be used when water is not available.

Welding with Water Cooling

This is the preferred method of welding. The water should not contact the exterior of the pipe.

End Options / Coupling Methods

Standard Weld Rings

- Most common style

- Typically no face seal weld

- Butt weld field applied

Victaulic End Styles

- Fast installation

- Low working pressure

Self-Aligning Weld Rings

- Male/Female recess

- Butt weld field applied

Standard Flanges

- 150#, 300# or 600# most common: others available

- Industry standard dimensions

- Raised face (shown) & plate flanges

Related Industries

- Aggregates

- Asphalt

- Cement

- Concrete

- Fundry

- Glass

- Material Handling

- Mining

- Power Generation

- Pulp and Paper

- Recycling

- Steel Mills

- Truck Builders