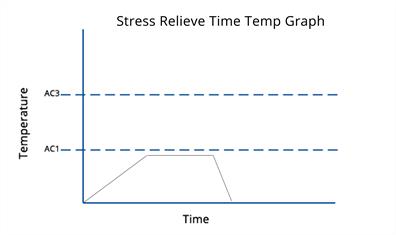

Anneal

In the annealing process there are three steps: heat, soak, and cool. To start, the steel is heated to the point of allowing recrystallization of the steel, which is considered the critical point (sometimes referred to the AC3 line). The steel is held at this temperature for a set amount of time before slowly cooling in the oven. It’s important for it to cool very slowly to produce a refined microstructure. Annealing reduces the steel’s hardness and increases the ductility, making it easier to machine. The soaking time is generally considered as an hour per inch of thickness. Positive results: increased ductility, improved machinability, enhanced electrical conductivity

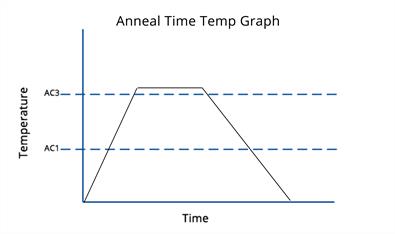

Normalize

The normalizing process is designed to relieve stresses, which results in improved ductility and toughness. The grain size is also enhanced and uniformed in this process. Similar to the annealing process, the steel is heated to a temperature just beyond the critical point (again, the AC3 line) and held for a set period of time. This is when the smaller grains and high-energy grain shapes form. The steel is then cooled to room temperature; unlike annealing, we take the steel out of the oven for this part of the process. The soaking time is generally the same as it would for anneal.Positive results: relieved stress, enhanced grain size, improved ductility, improved consistency of microstructure

Normalization is one of the most common industrialization processes. This is partly because it’s less expensive than annealing. Since the steel doesn’t have to cool in the oven, the furnace is ready for the next plate as soon as the soaking stage is complete. In annealing, the plate must cool in the oven, which could take 8 to 20 hours. Normalization also produces harder and stronger heat treat plate.

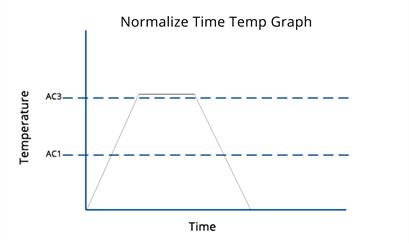

Stress Relieve

Another heat treat process for steel is stress relieving. As the title suggests, it reduces the residual stresses that may have been caused by hot rolling, welding, or cutting. With this process, the steel is heated to a temperature below the critical temperature, resulting in little to no change to the material properties like there is with annealing and normalizing. This is typically used on lower carbon materials, such as A36.These are all processes that prepare steel for further processing. They allow for an easier time in machining, forming, and help minimize distortion while being worked. If you have further questions about the annealing, normalizing, or stress relieving processes and how they may be beneficial to what you’re looking for, please contact a specialist with Clifton Steel.