If you live in an area where the weather is a bit unpredictable, but you can always count on the winters being cold, then this post is for you. If you don’t, then it’s still for you because your steel might be coming from a cold area. In Cleveland, we have been working with days in the single digit temperatures, negative with the wind chill. Why do you care if you don’t live here? The cold air can affect your steel, and we want to tell you about it so you know how to most effectively work with our product.

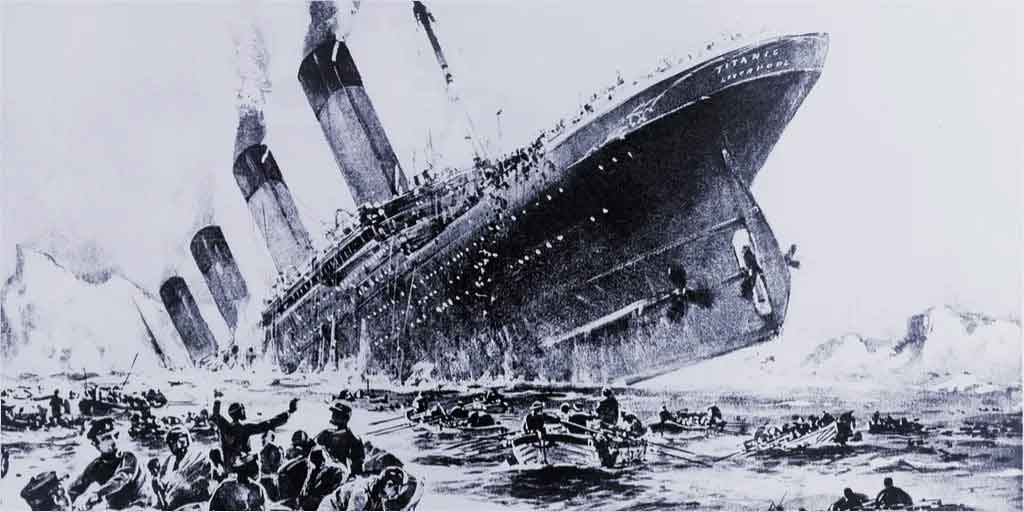

Life Example

Everybody is familiar with the sinking of the Titanic, but do they know why it sunk? I’m not just talking about it hitting an iceberg. It’s because the composition of the steel for the hull wasn’t equipped for the cold temperatures. Primarily, the steel became brittle when it was exposed to the cold water, and the colder it got the more brittle it became. When it finally hit the iceberg, the steel fractured much easier than it would have at warmer temperatures.

Luckily, we are more familiar with how the cold affects steel and the compositions used are more controlled to be able to avoid having another Titanic moment.

There are a few elements that have a direct impact on steel in the cold weather:

- Carbon – The more carbon, the more brittle the steel. Decrease the carbon, it’ll do better in colder temps

- Nickel – Nickel increases hardenability and toughness, which is beneficial when it comes to the Charpy impact test

- Manganese – Increase the manganese, increase hardness. It’s also an austenite stabilizer in the chilly temps

- Copper and aluminum retain tensile ductility at lower temperatures as well.

Metals that are typically ductile at room temperature may lose that in the colder temperature and become stiffer. Brittle transition temperature is the temperature where fractures in steel change from ductile to brittle. In other words, instead of bending, it breaks. The temperatures will differentiate based on how the steel is composed.

Testing

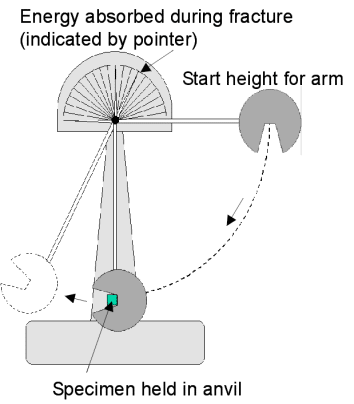

Charpy impact test, or V-notch test, is utilized to determine the amount of energy absorbed by steel during a fracture. The energy absorbed gives a measurement of toughness and helps determine the brittle transition temp. Two criteria needed to run the test are the amount of load (in foot/pounds) and the temperature of the sample. The test is relatively quick and cost-effective. It confirms that the steel will be able to stand up in weather conditions required for the end use.

The Solution

How do we make sure we don’t break our steel? By properly preheating before using it. During the colder months, we preheat plates that we may not normally in the warmer months. If it’s a thin plate, it could come to room temperature on its own within hours or days. The thicker the steel, the longer it takes to come to room temp. With thicker steel, it’s best to preheat it. If you let it come to temperature naturally, there’s a chance that the outside will be there, but the inside won’t. That could end up with thermal cracking in the middle of the plate, and nobody wants that. Once it’s brought back up to room temperature, you shouldn’t have to worry about any cracking.