Flattening methods

Press Brake

A press brake is a machine tool that utilizes dies. The metal is placed between a matching set of dies to get the desired shape. The top portion is mobile while the bottom die is stationary. The press brake uses a V-shaped die to do this to give enough room to bend the steel. If it was a flat surface, the steel would just bounce back to the bend. The steel will be placed in the press brake where a bend or bow is, the top press is lowered just enough to bend the steel beyond the yield point. When it’s released, the bend will be flattened out.

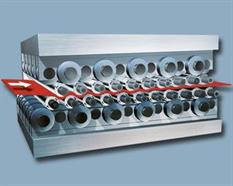

Roller Leveling

Roller leveling is essentially a bending process. The steel goes through a series of alternating bends, which are created by going through upper and lower sets of leveling rollers. The rolls are able to be individually set for precision. The metal moves through like a wave, where the entry has the biggest wave and smallest is at the exit point. The steel comes out flat because of the alternating bends and decrease of bend intensity.

Heat Treatment

This is not recommended since the steel gets heated above the tempering point. The extreme heat changes the properties of the steel, which you want to avoid if you aren’t specifically trying to. After the steel is heated to a high degree, it needs to be cooled evenly through the quenching process. A cooling medium (water, polymer, or oil) will be used to create the desired grain structure of the steel by spraying the steel from the top and bottom. If the quenching portion is done evenly, the plate will be flat. If for some reason the quench is uneven, the plate may have a slight bend or wave to it. If the plate isn’t within tolerance, the heat treat process isn’t as precise as it could be. In that instance, it is best to use a secondary flattening technique. Many heat treat processes do not control the quench operation to provide a flat surface. In this case, they rely on a subsequent flattening method such as roller leveling or press braking to address the uneven control of quenching.

Realistic expectations

While I would love to be able to tell you to expect all of the steel you order to be perfectly flat, that wouldn’t be the case. It’s not a naturally flat material, but there are ways to flatten it out. Industry-wide standards exist, however that doesn’t mean they will match the tolerance that you require. Most of the time, people don’t take that into consideration to account for additional costs to reach their tolerances needed. It’s necessary to understand the manufacturing tolerances in order to determine if they meet your finished product tolerance, or if a flattening method is needed.

Another thing that tends to be overlooked is what happens to the flattened steel when it’s cut. Your pieces may not remain as flat as the plate. That is because when steel is flattened, stresses are caught inside the metal. When the metal is cut by saw, plasma, laser, waterjet, oxyfuel, or the steel is welded, those stresses are released. That can result in the cut pieces being less flat than the steel plate. Those pieces can sometimes be flattened to reach the tolerances needed.

Tolerances

Tolerances are different for every plate, depending on length, width, thickness, and type of steel. We talked about how ASTM created standards to follow, but companies are also able to set their own tolerances beyond that. For example, here at Clifton, we strive for ½ of the ASTM A6 standard. Although ASTM is the most widely used specification for flatness, some products have developed their own flatness specs, so a review of the spec you are using is advised.

Below is an example of part of the ASTM A6 commercial standards for heat treated plate. Contact us for further information on flatness tolerances.

| Specified Thickness | Permissible variations from A Flat Surface for Specified Widths, In. |

| in inches | to 36, Excl. | 36 to 48, Excl. | 48 to 60, Excl. | 60 to 72, Excl. |

| to 1/4, excl. | 13/16 | 1-1/8 | 1-3/8 | 1-7/8 |

| 1/4 to 3.8, excl. | 3/4 | 15/16 | 1-1/8 | 1-3/8 |

| 3/8 to 1/2, excl. | 3/4 | 7/8 | 15/16 | 1-1/8 |

Flatness is a property of steel that is often not fully understood, and if not reviewed can make a huge difference in the profitability of your project. If you are unsure about flatness of a particular product or wish to discuss, please feel free to contact a specialist with us!